Dependable Welding Inspection Service for Quality Control

Dependable Welding Inspection Service for Quality Control

Blog Article

Enhance Your Projects With Specialized Welding Providers: Benefits and kinds

As developments in innovation continue to shape the welding market, comprehending the kinds of specialized welding solutions available and the benefits they use is critical for remaining ahead in a competitive market. Whether it's the impact on building and construction projects, the applications in the manufacturing market, or the benefits for numerous markets, discovering the realm of specialized welding solutions introduces a globe of possibilities that can elevate projects to brand-new heights.

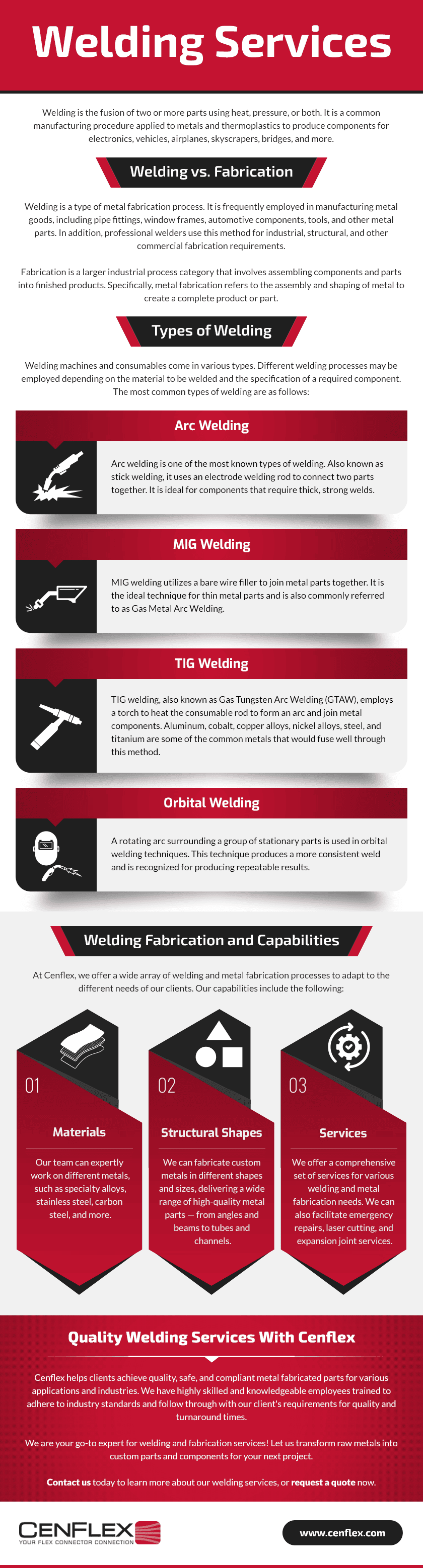

Kinds Of Specialized Welding Services

Specialized welding services encompass a series of methods customized to particular industrial applications, consisting of however not limited to TIG welding, MIG welding, and immersed arc welding. Tungsten Inert Gas (TIG) welding, known for its precision and clean welds, is commonly utilized in industries needing top quality welds on materials like stainless steel and light weight aluminum. Steel Inert Gas (MIG) welding, on the other hand, is liked for its efficiency in taking care of thicker products and high manufacturing rates, making it a preferred selection in automobile and building and construction sectors. Immersed Arc Welding (SAW) entails the development of an arc between a constantly fed cord and the workpiece, protected by a layer of granular change. This approach is optimal for welding thick products in a single pass, commonly made use of in shipbuilding and facilities tasks.

Each of these specialized welding strategies supplies unique advantages tailored to details job demands, highlighting the value of choosing the proper approach based upon material, density, and desired weld qualities.

Benefits of Specialized Welding Services

The advantages of using specialized welding solutions in commercial applications are manifold, ranging from boosted precision to enhanced effectiveness in handling certain materials and project demands. One significant benefit of specialized welding solutions is the experience and experience that welders bring to the table. These specialists are trained in various specialized welding strategies, making sure that the welding process is performed with the highest possible degree of skill and precision.

Effect on Construction Tasks

Drawing on the proficiency of specialized welding solutions in industrial applications, the effect on construction projects is significant in regards to precision, effectiveness, and general top quality of welds. Construction tasks rely heavily on the architectural stability of bonded elements, making the accuracy offered by specialized welding critical. By making use of specialized welding solutions, building and construction groups can make sure that each weld meets the required specifications, decreasing the threat of architectural failings.

Moreover, specialized welding methods improve effectiveness in building and construction tasks by streamlining the welding process. With specialized tools and trained professionals, jobs that would certainly or else be time-consuming can be completed extra swiftly without compromising top quality. This effectiveness not just accelerates task timelines however likewise reduces labor prices related to welding.

In addition, the overall quality of welds in building jobs is considerably enhanced via specialized welding services. These services commonly involve advanced more info here welding innovations and highly proficient welders that can develop stronger, more durable welds. The remarkable quality of welds achieved with specialized solutions adds to the durability and integrity of building and construction projects, guaranteeing that structures continue to be sound and safe for several years ahead.

Applications in Production Market

Within the production market, the utilization of specialized welding solutions plays a vital role in ensuring the integrity and performance of production procedures. Welding is a fundamental process in production, made use of in different applications such as joining metal parts, producing frameworks, and fixing tools. Specialized welding methods like TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and robotic welding are thoroughly used to fulfill the sector's particular requirements.

One find more significant application of specialized welding in manufacturing is in the automotive field. Welding is crucial in the assembly of car components, making sure structural security and security. Additionally, the aerospace sector heavily counts on specialized welding services to make airplane parts with high accuracy and toughness to hold up against extreme conditions.

Additionally, in the manufacturing of machinery and equipment, specialized welding plays a crucial duty in creating reliable and long lasting products. By utilizing sophisticated welding approaches, producers can improve product top quality, boost production performance, and eventually provide superior products to the market - Welding Inspection Service. The elaborate and precise nature of specialized welding solutions makes them important in the production sector's quest for development and quality

Benefits for Various Industries

With the critical function that specialized welding services play in the production sector, it is apparent that their benefits prolong throughout numerous sectors, providing necessary advantages for different markets. Specialized welding services provide enhanced precision and next page top quality control, making sure that the final product meets rigorous market requirements. Furthermore, specialized welding solutions can assist industries fulfill particular regulatory demands, such as those in the oil and gas industry or the nuclear industry, where safety and security and dependability are extremely important.

Conclusion

In verdict, specialized welding services offer a series of advantages for construction tasks and the production industry. With different types of welding services offered, such as robotic welding and laser welding, businesses can boost the quality and performance of their jobs. The impact of specialized welding solutions extends throughout several industries, supplying advantages in terms of longevity, accuracy, and cost-effectiveness. Welcoming specialized welding solutions can result in enhanced job outcomes and increased competitiveness in the market.

As innovations in technology continue to form the welding market, recognizing the kinds of specialized welding solutions available and the benefits they provide is crucial for staying in advance in a competitive market.Specialized welding solutions incorporate a range of methods tailored to details industrial applications, including yet not limited to TIG welding, MIG welding, and submerged arc welding.Additionally, specialized welding solutions frequently make use of advanced devices and modern technologies that are especially designed for complicated welding jobs. Specialized welding methods like TIG (Tungsten Inert Gas) welding, MIG (Steel Inert Gas) welding, and robot welding are extensively utilized to meet the sector's details demands.

Report this page